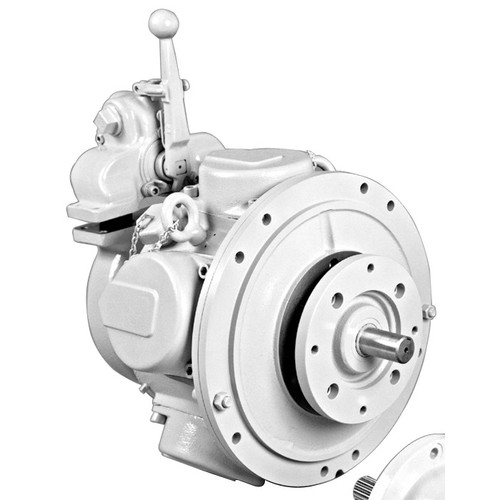

Ingersoll Rand

Ingersoll Rand’s KK5B Series Pneumatic Motors are engineered for high-performance, providing exceptional torque and power in a variety of industrial applications. Designed for tough environments, these motors excel at low-speed, high-torque operations, making them ideal for demanding tasks such as lifting heavy loads, driving automated machinery, and powering conveyors. The KK5B Series is built with durability in mind, utilizing rugged materials to ensure reliability and long service life even under harsh conditions like dust, moisture, and extreme temperatures. Their air-driven design eliminates the risk of sparks, making them safe for use in explosive and hazardous environments, such as chemical plants and oil refineries. These motors are energy-efficient, offering reduced operating costs compared to electric motors, and their low-maintenance design minimizes downtime. With the ability to adjust speed and torque through simple air pressure control, the KK5B Series offers flexibility to meet a wide range of industrial requirements. Whether used for material handling, manufacturing, or automated processes, Ingersoll Rand KK5B Pneumatic Motors are a powerful, reliable, and cost-effective solution for heavy-duty industrial operations.

Features:

Tech Tip: To increase tool performance, extend tool life and lessen repair cost use it with a Filter-Regulator-Lubricator (Click Here To Shop FRLs)

Need more information? Feel free to contact us with your requirements via phone at 800-608-5210 or e-mail at info@intlairtool.com

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand

Ingersoll Rand