Posted by Mark W. Schieber on 21st May 2020

How to Choose the Right Pneumatic Impact Wrench for Your Industrial Bolting Application

Air powered Impact wrenches, also referred to as impact guns, impactools, or simply air impacts, are specialty fastening tools designed to deliver high amounts of torque to a nut or bolt. By utilizing an anvil and hammer style mechanism, impact wrenches require only minimal effort from the user.

Impact wrenches are popular in: automotive, aerospace, heavy equipment maintenance, construction projects, vehicle service and product assembly.

While the basics of an impact wrench remain the same across styles and manufacturers, there are differences in torque output, drive sizes, and the physical configurations of the tool. At International Air Tool Company, our goal is to provide premium quality pneumatic impact wrenches at reasonable prices. Given their proven quality and durability over time, we recommend American made air tools to our customers whenever economically feasible.

We stock the most common size impact wrenches in our local inventory here in San Diego, California which means fast shipping to you. We back up our tools with outstanding technical assistance and responsive customer support. Our team can help you choose the right tool for the job, the first time around.

As you consider the impact wrench options on the market, take some time to read through the following buying guide. This guide will walk you through the basics of how impact wrenches work, sizing choices, and the top manufacturers of these tried and true bolting tools.

The Basics of Impact Wrenches

The Basics of Impact Wrenches

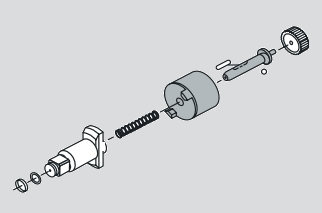

Impact wrenches transfer energy from a rotating mass, which is accelerated by a motor, into energy storage. The energy then connects to an output shaft where it is delivered in rapid bursts via the tools anvil, creating high amounts of torque.

Because the output shaft is designed with a hammer-like shaft that moves freely, the user experiences no reaction during run down. It should be noted however, that impact wrenches are not meant for precision torque application and cannot be set to shut off at a specific torque once the desired tightness is achieved.

Nevertheless, impact wrenches are a critical component of varying assemblies of products, structures, and vehicles. Throughout any given day, you encounter the benefits of impact wrenches all around you. From the cars we drive to the massive power lines that tower over highways, impact wrenches are responsible for heavy-duty bolting across the globe.

Cordless or Pneumatic?

Cordless or Pneumatic?

As you consider the impact wrenches available on the market, one determining factor in your final purchase will be which power option you decide on.

The following are the most common power source choices for impact wrenches:

- Air Powered or Pneumatic

- Battery Powered Cordless

Compressed air is the most popular choice. This is where the term pneumatic impact wrench is derived from. By connecting these tools to a sufficiently powered air compressor, the wrench transfers air flow into an energy source responsible for accelerating the rotating mass, which then stores the power to be dispersed in bursts to the shaft.

In most cases, the chosen power source will be dictated by the setup of your job site or business operation. If you are already utilizing a pneumatic tool system, we recommend staying the course as an air-powered impact wrench offers the greatest durability. Conversely, cordless impact wrenches have become an increasingly popular choice for consumers who might not have access to compressed air.

Drive Size

Drive Size

After determining the power source for your impact wrench, you will want to consider what size wrench is right for your application. The size of an impact wrench is referred to by the drive size (anvil size) and is measured by the distance between the flat edges on the anvil.

The following are the most common sizes for these specialty wrenches:

- ¼”

- ⅜”

- ½”

- ¾”

- 1”

For consumer applications, ¼” to ⅜” impact wrenches are common. These smaller anvils deliver enough torque to handle your average job around the house without fear of stripping or over-tightening. Most have an integrated adjustable clutch. We are not real strong in this department.

The slightly larger options, such as ½” and ¾” impact wrenches, are commonly utilized in commercial applications such as garages and tire shops. Their is a direct relationship between the drive size and the amount of torque the tool puts out. Additionally, larger tools are typically better suited for more taxing applications.

1” and 1-1/2" drive impact wrenches are designed for use at refineries, mines, power plants, and large construction jobs.

Choosing the Right Manufacturer

Choosing the Right Manufacturer

When purchasing impact tools, a key factor will be choosing the right manufacturer for your needs. With numerous options on the market, it is important to hone in on brands backed by years of trusted service. Quality tools are worth the investment, as they will provide you with reliable service over the years to come.

A few top manufacturers of impact wrenches include Ingersoll Rand, Sioux Tools, Chicago Pneumatic, and Cleco. These companies are esteemed for designing pneumatic and cordless impact wrenches that are reliable, durable, and capable of delivering incredible power.

Below, you can compare the different benefits each trusted manufacturer delivers, as well as the options provided by each brand.

Ingersoll Rand Impact Wrenches

Ingersoll Rand has been designing quality impact tools since 1934. This trusted brand offers air powered and cordless impact wrenches to meet a variety of needs.

Choose from three different performance levels: The following are Ingersoll Rand’s definitions of their classifications:

- Super-duty: These tools utilize advanced technology to offer extreme durability and strength. Super-duty impact wrenches are for extreme applications and are manufactured in the USA.

- Heavy-duty: Models that fall under this designation are designed for excellent power paired with accuracy and speed control. These tools are best for demanding applications and environments. These are a mix of USA made and imports depending on the series.

- Maintenance-duty: Commonly used in the automotive industry, maintenance-duty wrenches are engineered for frequent use in tire shops and garages. These tools offer an excellent power to weight ratio for lightweight handling.

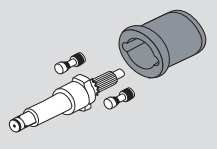

Another option to consider when shopping Ingersoll Rand products is the type of impact mechanism present in the hammer case . The hammer is responsible for generating the torque which is eventually delivered to the fastener. The following are the styles of hammers offered by Ingersoll Rand:

- Twin Hammers - A great option when the job requires a lot of power per pound in hard or soft-draw applications. Twin Hammers are also less sensitive to to the air pressure fluctuations than other impact mechanisms.

- Jumbo Hammers are very similar to the Twin Hammer design, they utilize one large single hammer.

- Ball and Cam - This design is a great choice for applications that require a soft-draw, and are commonly utilized on larger impact tools.

|

|

|

|

Twin Hammers |

Jumbo Hammers | Ball and Cam |

Other considerations when choosing an Ingersoll Rand impact wrench include:

Blows per minute |

Max. torque |

Torque range |

Tool weight |

Tool length |

Sound level |

Vibration level |

Max. air consumption |

A good place to begin when comparing Ingersoll Rand’s impact wrenches is their selection of industrial impact wrenches versus their maintenance duty impact wrenches.

Sioux Tools Impact Wrenches

Sioux Tools a division of Snap-On, has been building tools for over 100 years. Sioux has been a long-trusted name in the air tool industry. This company delivers powerful wrenches, capable of exerting up to 2500 Ft. Lbs. (1-1/2" drive model) They're also known for their premium-quality materials and advanced designs.

Sioux Tools focuses on faster run-down speeds with improved accuracy and consistent torque delivery. They have a keen concentration on safety, understanding that a malfunctioning tool can result in serious injury to the user.

For this reason, Sioux Tools are used across an array of heavy-duty applications where keeping a job site injury free is a high priority.

The following criteria should be considered when choosing a Sioux Impact Wrench:

Class of Service

- High production — automobile assembly plants, farm, and construction equipment, etc.

- Low production — large machinery assembly

- Maintenance or repair work

Job Conditions

- Hard pull-up — rigid joint

- Soft pull-up — spring joint

- Run-down — free-running, or prevailing torque (lock nut, self-threading screw)

Material

- Metal-to-metal

- Metal/gasket

- Rubber or plastic

Assembly Method

- General tightening — operator judgment

- Turn-of-the-nut — permanent assemblies (steel erection and construction equipment)

Features

- Ball & Cam or Twin Hammer impact mechanisms

- Inline, pistol grip, or D-handle configurations

- Pin, friction ring, quick change, or thru-hole socket retainers

- Standard or extended anvils

Chicago Pneumatic Impact Wrenches

Another well-known name in the manufacturing of pneumatic impact wrenches is Chicago Pneumatic. This company focuses on the use of cutting-edge technology and materials. You will find wrenches that implement composite and steel housing options for the toughest applications in the harshest environments. CP Impacts are great in the oil field, platform, mine, or refinery.

Whether you are shopping for a general maintenance tool or a production bolting capable wrench, Chicago Pneumatic offers an unrivaled line of options. Their versatile line of wrenches is often classified by the varying clutches they utilize. Another important distinction of Chicago Pneumatic wrenches is their vast range of sizing options, from ⅜” to a whopping 2½” square drive.

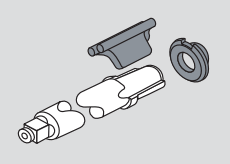

When you select a bolting tool from Chicago Pneumatic, after selecting your drive size, have a look at the different handle styles on offer:

|

Pistol (P) Grip |

D-Handle Inside Trigger (D I T) |

D-Handle Outside Trigger (D O T) |

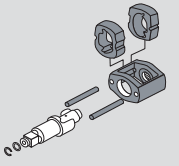

Next, you will want to consider the different clutch options, including the DYNA-PACT pin clutch which is great for smooth operation when working with hard joints, the 2-jaw for the smoothest action and best control, the twin hammer which is an industry standard (your all around clutch), or the rocking dog pinless clutch which is great for soft joints.

|

DYNA-PACT (Pin clutch) |

Twin Hammer (Double Dog) |

Rocking Dog (Pinless or Double) |

2-Jaw |

Utilizing Chicago Pneumatic’s industrial tool catalog can help you compare and contrast their tools, complete with torque range comparison charts. If you decide to purchase a CP impact. you will enjoy the benefit of their comfort-focused design with durability that can hold up to the most rigorous of jobs.

Cleco Impact Wrenches

Finally, no buying guide would be complete without mention of Cleco impact wrenches. Cleco, founded in 1894 as Cleveland Pneumatic Tool Company, has been a trusted manufacturer of pneumatic tools for years.

Cleco focuses on durability and excellent performance, offering tools to assist in the automotive, aerospace, agriculture, assembly, and oil/gas industries.

Cleco offers four main product categories for impact wrenches. If you are considering the purchase of a Cleco impact wrench, check out the following four categories, each designed to meet the specific needs of varying jobs.

- Cleco CV Series Composite Impact Wrenches: If you are looking for a lightweight, comfortable impact wrench, the CV Series is for you. These wrenches are ideal for general repair and maintenance work. CV Series wrenches are economical, while still providing high-quality functionality.

- Cleco CWC Premium Composite Impact Wrenches: One of the signature benefits of Cleco wrenches is how lightweight they are while still offering necessary torque. The CWC Premium Composite Series is ideal for heavy-duty applications. These wrenches feature a twin hammer, triple cycle heat treatment, a variable-speed trigger, one-handed forward/reverse operation, and a vibration-resistant handle. Ranging from ¼” to ¾” sizing, these impact tools are excellent for rugged applications.

- Cleco CWM Series Metal Housing Pneumatic Impact Wrench: For an extremely durable, rugged pneumatic impact wrench, look no further than the CWM Series featuring metal housing. These impact wrenches were put through a series of tests involving everything from exposure to extreme elements to being dropped two stories. The end result is an impact wrench that can handle even the roughest of job sites. This makes these wrenches ideal for industries such as the oil and gas industry, construction sites, and agricultural applications, where the job site environment is taxing.

- Cleco WT Metal Housing Rear Grip Impact Wrenches: For heavy-duty applications, the WT Metal Housing Rear Grip impact wrenches are a must. Cleco focuses on exceptional torque with outstanding rear grip, offering ease of use and maximum efficiency. With incredible bolt size options, ranging from 1 ⅜” to 1 ½”, these wrenches are perfect for heavy-duty manufacturing, oil field applications, and other rigorous jobs.

- Cleco MP Series Wrenches: Cleco is known for its unique impact wrenches designed for specific applications. The MP Series is a rugged series designed specifically for soft draw applications, which is ideal for use with wood or aluminum. The efficient design of the wrench allows for minimal exertion from the user.

Click Here To Shop Our Catalog of Impact Wrenches

As you consider the different power options, sizing choices, and manufacturers, our team is here to help. We can walk you through the process and help qualify the application. Our team provides expert tech support and friendly Customer Service.

For help choosing the correct Impact Wrench, please call (800) 608-5210 or email info@intlairtool.com