24th Jun 2024

Level Up Your Grinding: Why You Need the Pferd CC Grind System in Your Metal Fabrication Toolkit

Welders and metal fabricators know the importance of good grinding wheels. They remove, shape, and smooth metal. However, traditional options can be slow, loud, and even dangerous. Enter the Pferd CC Grind System, a revolutionary grinding solution that redefines effectiveness and safety.

The CC grind is designed for efficiency and precision as it offers a superior alternative to traditional grinding wheels, which makes it an invaluable tool for metalworking professionals. Read on as we discuss the features and benefits of the Pferd CC Grind System, why it's a must-have in your metal fabrication arsenal, and how to use it safely.

What Is the Pferd CC Grind System?

The Pferd CC Grind System is a next-generation abrasive disc engineered for high-performance grinding tasks on various metals. It merges the power of a grinding wheel with the versatility of a flap disc to offer the best of both worlds.

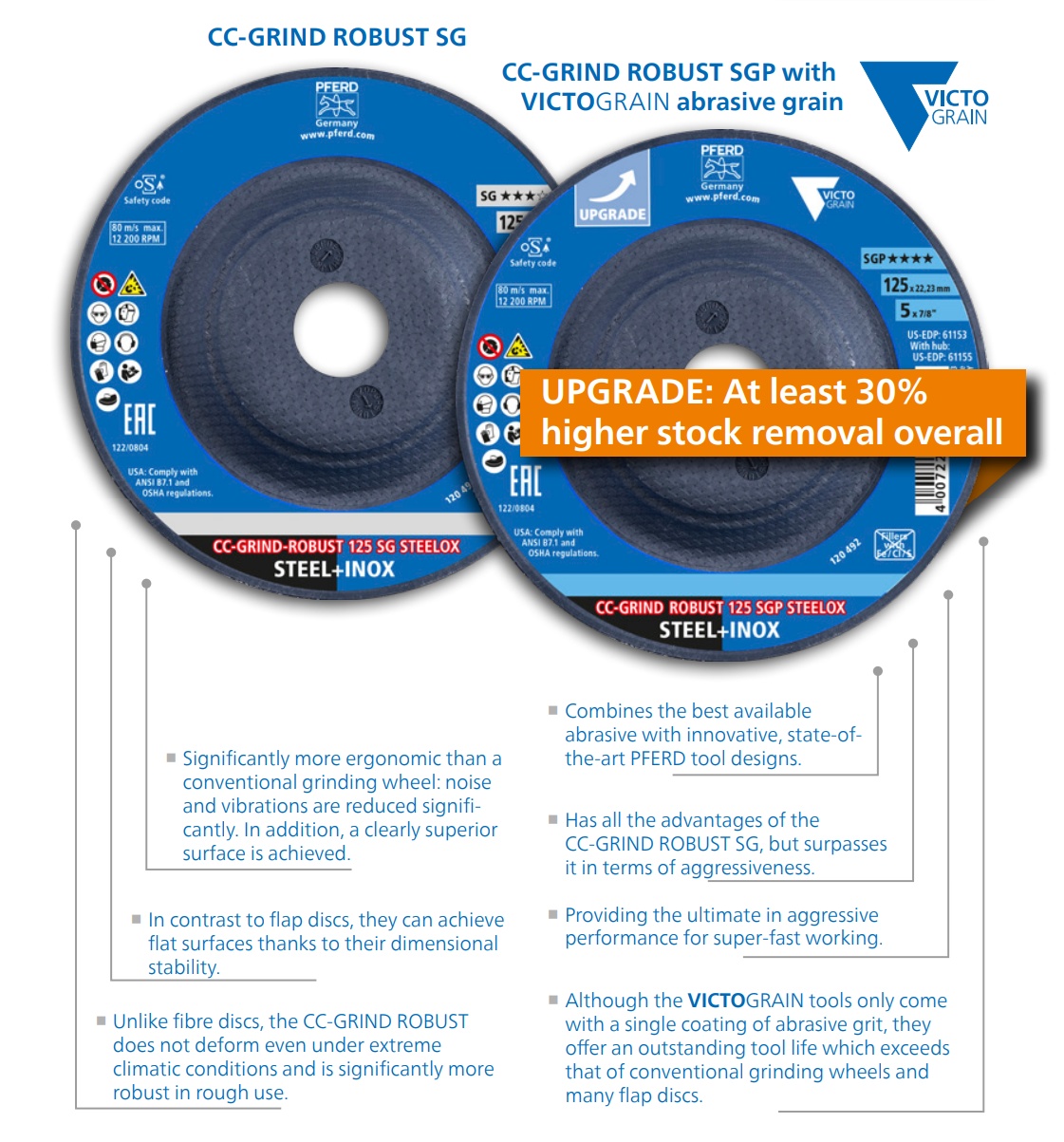

Unlike traditional grinding wheels with a less aggressive aluminum oxide grain, the CC Grind features a special ceramic abrasive grain known as VICTOGRAIN. It's a highly aggressive material that enables a faster cut rate while maintaining a cool operating temperature. Using it translates to less grinding time and reduced risk of heat-related warping or discoloration on the workpiece.

The Pferd CC Grind System features a glass fiber backing pad, providing a stable and safe platform for grinding. This construction ensures durability and enhances user safety by minimizing hand-arm vibrations and noise levels.

A layered structure of the glass fiber backing pad is specifically engineered to match the rigidity of traditional grinding wheels, ensuring a familiar feel and confidence during use. However, the CC Grind System creates a more comfortable and safer work environment for extended periods than conventional grinding wheels.

One of the standout features is its ergonomic design. The tool reduces noise by 50% and vibrations by 50%. It also produces 80% less dust, which makes it a more health-conscious choice for metalworkers. Combining the ceramic abrasive grain and the fiberglass backing plate boosts efficiency to decrease operator fatigue and enhance productivity.

Why Should You Use the Pferd CC Grind System?

The CC Grind System shines in numerous metalworking applications, including surface grinding, weld dressing, chamfering, and deburring.

- Surface grinding allows machinists to achieve a smooth, uniform finish on metal stock for subsequent machining or painting.

- Weld dressing removes excess material and refines the weld profile to create a clean and functional weld joint.

- Chamfering creates a beveled edge on the workpiece for improved aesthetics, stress reduction, or easier welding.

- Deburring tackles any unwanted sharp edges or imperfections left behind from cutting or machining processes to improve the safety and functionality of the ready-to-use final product.

Together, these applications emphasize the versatility of the Pferd CC Grind System. The tool's aggressive abrasive action permits rapid stock removal, which makes it perfect for demanding grinding tasks.

The Pferd CC Grind System enhances productivity by reducing the time needed for grinding operations. Its ergonomic design minimizes operator fatigue, thus leading to improved work quality and safety. Decreasing noise, vibrations, and dust also creates a healthier and more comfortable working environment, contributing to overall job satisfaction and efficiency.

An In-Depth Comparison of 5 CC Grind Products

There are several versions of the Pferd CC Grind System, each tailored to specific applications. Here's a detailed look at five prominent products in this lineup:

CC Grind Solid

This all-rounder is a great alternative to traditional grinding wheels since it delivers exceptional performance on various ferrous metals. Its solid construction ensures stability for heavy-duty grinding, chamfering, deburring, and working on weld seams. The tool features a highly aggressive abrasive grit that ensures rapid material removal and an improved surface finish. Its layered glass fiber backing pad guarantees durability and safety, while the ergonomic design reduces dust, noise, and related vibrations.

CC Grind Flex

Ideal for curved surfaces and intricate details, the CC Grind Flex offers superior flexibility without compromising on cutting power. It's engineered explicitly for work on weld seams, which are the joints where two pieces of metal are fused. This tool allows for the complete smoothing of butt welds to eliminate visible dents and bumps after painting or varnishing.

Like the CC Grind Solid, it features an aggressive abrasive grit and a layered glass fiber backing pad. It also offers the same ergonomic benefits: an excellent choice for detailed grinding tasks.

CC Grind Strong - 3 Resin Fiber Discs and an 1/8" Grinding Wheel in One Disc!

Metalworking professionals looking to reap the benefits of traditional grinding wheels and the modern CC Grind Solid now have the CC Grind Strong as the perfect intermediary. Particularly designed for stainless steel and high tensile strength steels, it tackles even the toughest materials with ease.

The CC Grind Strong provides three times the tool life of the CC Grind Solid SG Steel due to its unique backer that grinds and three abrasive layers that can be worked through sequentially. It's suitable for surface grinding, chamfering, deburring, and working on weld seams, offering fast work progress and improved surfaces compared to conventional grinding wheels.

CC Grind Robust

As the name suggests, this version of the Pferd CC Grind System offers a high-performance, ergonomic option for grinding wheels, fiber discs, and flap wheels. This champion of durability excels in heavy grinding applications, especially when working with steel and stainless steel. The CC Grind Robust's construction ensures it does not deform under extreme conditions, maintaining its effectiveness and safety. Thanks to its adapted geometry, it shrinks noise and vibrations and does not require a clamping flange set.

CC Grind View

This version of the Pferd CC Grind System combines a transparent design with a high-performance VICTOGRAIN abrasive disc. The innovative viewing window strategically placed on the disc lets you see exactly where the disc is making contact with the workpiece.

This is particularly beneficial for detail work or intricate grinding tasks where maintaining a consistent line or angle is crucial. The viewing window also eliminates the need for constant disc repositioning, which minimizes wasted movement for improved work efficiency. Ergonomically, the CC Grind View maintains the system's signature lightweight design and reduced vibration for operator comfort.

A fiberglass backing plate ensures the CC Grind View maintains its structural integrity throughout use. It's a key safety factor that provides a stable platform for grinding while minimizing the risk of disc breakage.

How to Safely Use the Pferd CC Grind System

Always follow the manufacturer's guidelines and safety protocols. Wear appropriate personal protective equipment (PPE) such as eye protection, hearing protection, gloves, and a dust mask.

Only use a grinding disc specifically designed for the material you are working with, whether it be steel, stainless steel, or any other metal, for optimal performance and safety.

Verify that the tool adheres to EN 12413 and EN 13743 safety standards: they cover bonded and coated abrasives, respectively, to guarantee it has undergone rigorous testing and is safe for use.

Always check for the "oSa" (Organization for the Safety of Abrasives) mark, which indicates that the product complies with these safety regulations. When using the tool, maintain a flat contact angle and apply even pressure. Avoid using the peripheral edges of the disc; instead, use the face of the disc for grinding.

Regularly inspect the tool for any signs of damage and replace it if necessary. Look for cracks or fractures in the disc, which can compromise its structural integrity and lead to failure during operation. Check for uneven wear patterns, as they can indicate improper use or alignment and affect grinding performance.

Be sure the abrasive surface has not worn down excessively, as this can reduce the tool's effectiveness and increase the risk of accidents. Inspect the backing pad for any signs of damage or deterioration, as this can also impact the tool's safety and functionality.

What Can You Expect From Using the CC Grind System?

Upgrading to the Pferd CC Grind System has numerous benefits. The most immediate advantage is the considerable boost in productivity due to faster material removal rates. This efficiency translates to cost savings and decreased downtime for metalworkers. Other positives include:

- Enhanced User Comfort: The tool's ergonomic design lowers operator fatigue, allowing longer working periods without compromising quality.

- Reduced Noise and Vibration: Its users work comfortably in a quieter environment with less operator fatigue. This creates healthier work surroundings, which improves job satisfaction and general health.

- Cooler Operating Temperatures: This is a game-changer for metal fabrication. Since the CC Grind System minimizes heat build-up on the workpiece, it drastically reduces the risk of warping; a common issue that can ruin entire pieces and require costly reworks. Cooler temperatures further prevent discoloration, especially on delicate metals; hence, a clean and professional finish.

- Extended Disc Life: The durable construction of the CC Grind discs translates to a longer service life.

Invest in Efficiency and Safety With the Pferd CC Grind System

International Air Tool and Industrial Supply Co. is your trusted distributor for various industrial brands in the metalworking sector. We cater exclusively to B2B industries, providing manufacturing and metalworking professionals with high-quality tools and expert technical support.

Visit our website to explore our comprehensive catalog of Pferd CC Grind Grinding Discs. You can also call our sales team at (800) 608-5210 to discuss your metal fabrication needs and get a quote!